ELIMINATE PRODUCTION LINE FAILURES

Problem-solving

tool for minimizing

product defects

Increase production efficiency by 20 %, proven effective by industry experts.

This tailor-made application allows you to:

- end repetitive issues

- ensure high manufacturing quality

- protect your company's reputation

Experience the difference with Solvedio:

Boost manufacturing efficiency

By systematically resolving production issues, their reccurence can be significantly reduced. This frees up resources for high-priority tasks, leading to 30% faster deliveries.

Maintain high quality standards

Identifying and resolving production issues in real time significantly enhances production performance, customer satisfaction, and company reputation.

Identify assembly flaws early

Fast resolving of errors is essential for maintaining a consistent workflow. By minimizing unexpected disruptions, you eliminate risk of production downtimes.

Use tailor-made setup

Solvedio has been successfully implemented across various industries, from SMEs to large corporations. Its adaptability allows for effective deployment in your production environment as well.

Save production costs

Rapid problem identification prevent unforeseen financial losses stemming from material waste, rework processes, and product defects, eliminating the production delays as well.

Track all issues in one place

Solvedio centralizes problem management tracking for all production issues in a user-friendly cloud-based application. It also facilitates remote team collaboration on tasks.

See Solvedio deliver results

+ 20 %

production efficiency enhancement

+ 30 %

more efficient delivery process

96 %

tracked and solved issues

Discover the impact through a real case

Řešení auditu zdraví a bezpečnosti

Bez námahy digitalizujte své bezpečnostní procesy – od hlášení incidentů až po zavádění preventivních opatření.

Řešení neustálého zlepšování

Podpořte zaměstnance, aby vnímali změny a dosahovali významných zlepšení napříč vaší organizací.

Řešení preventivní údržby

Zajištění optimálního výkonu zařízení, minimalizace prostojů a zvýšení provozní efektivity.

Řízení životního cyklu produktu

Objevte potenciál vývoje produktů a podpořte svůj tým při tvorbě výjimečných a kvalitních produktů.

Řešení řízení služeb na místě

Využijte zaznamenávání požadavků na služby, sledování pokroku v reálném čase a optimalizované řízení inventáře.

Řešení auditu

Zajištění optimálního výkonu zařízení, minimalizace prostojů a zvýšení provozní efektivity.

Investigate any problem quickly with best practices and digital tools

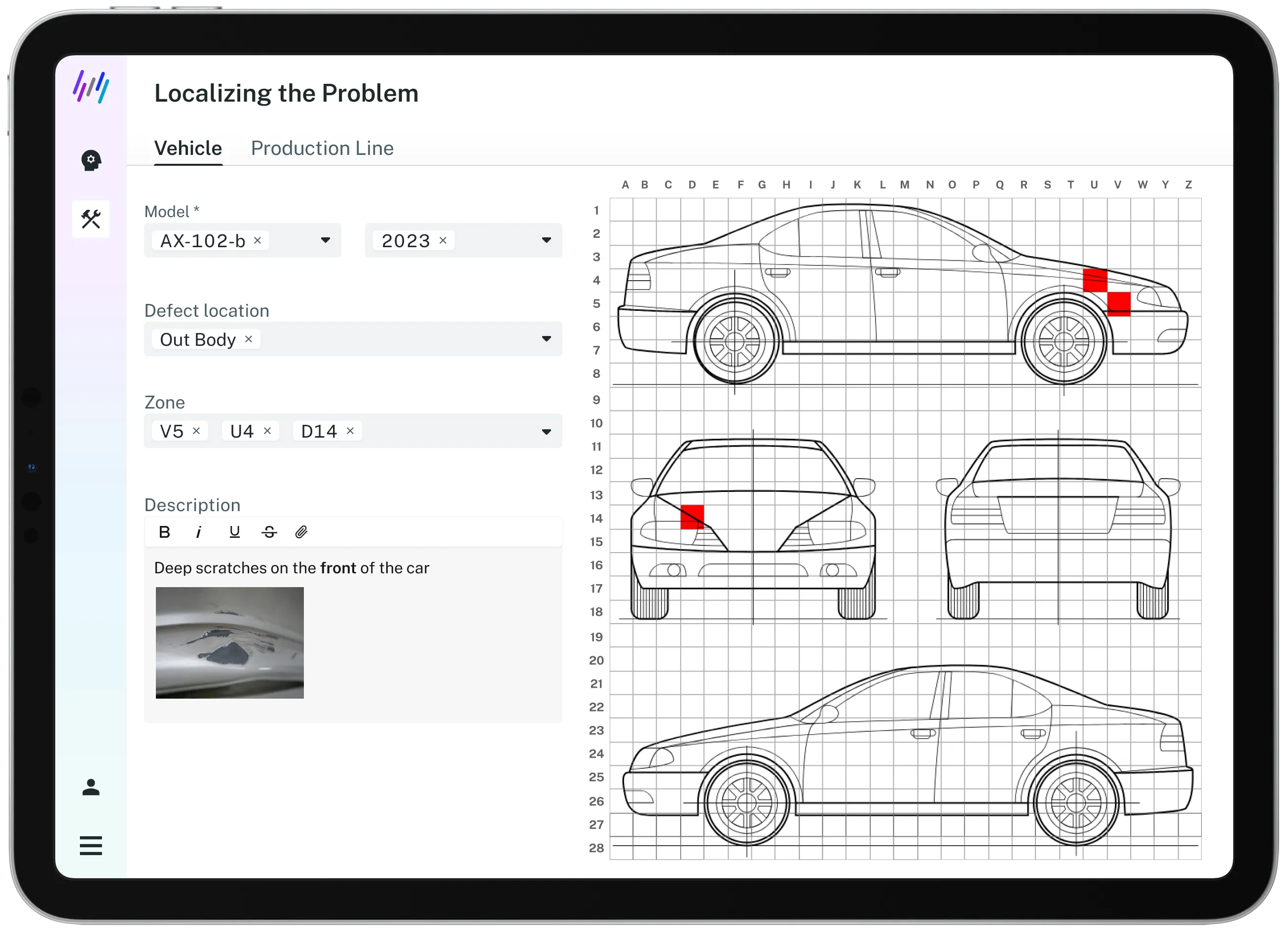

Accurate Problem Localization in Production

Problems can be registered from anywhere through any device directly by the line workers.

Finding the Root Causes of Problems

Identify occurring adverse events and flag critical failure points with digital tools such as Zero Analysis, 5 Whys or Fishbone.

Temporary and Permanent Corrective Measures

Propose measures to immediately prevent problems and incidents in production and permanent measures to ensure that they do not recur.

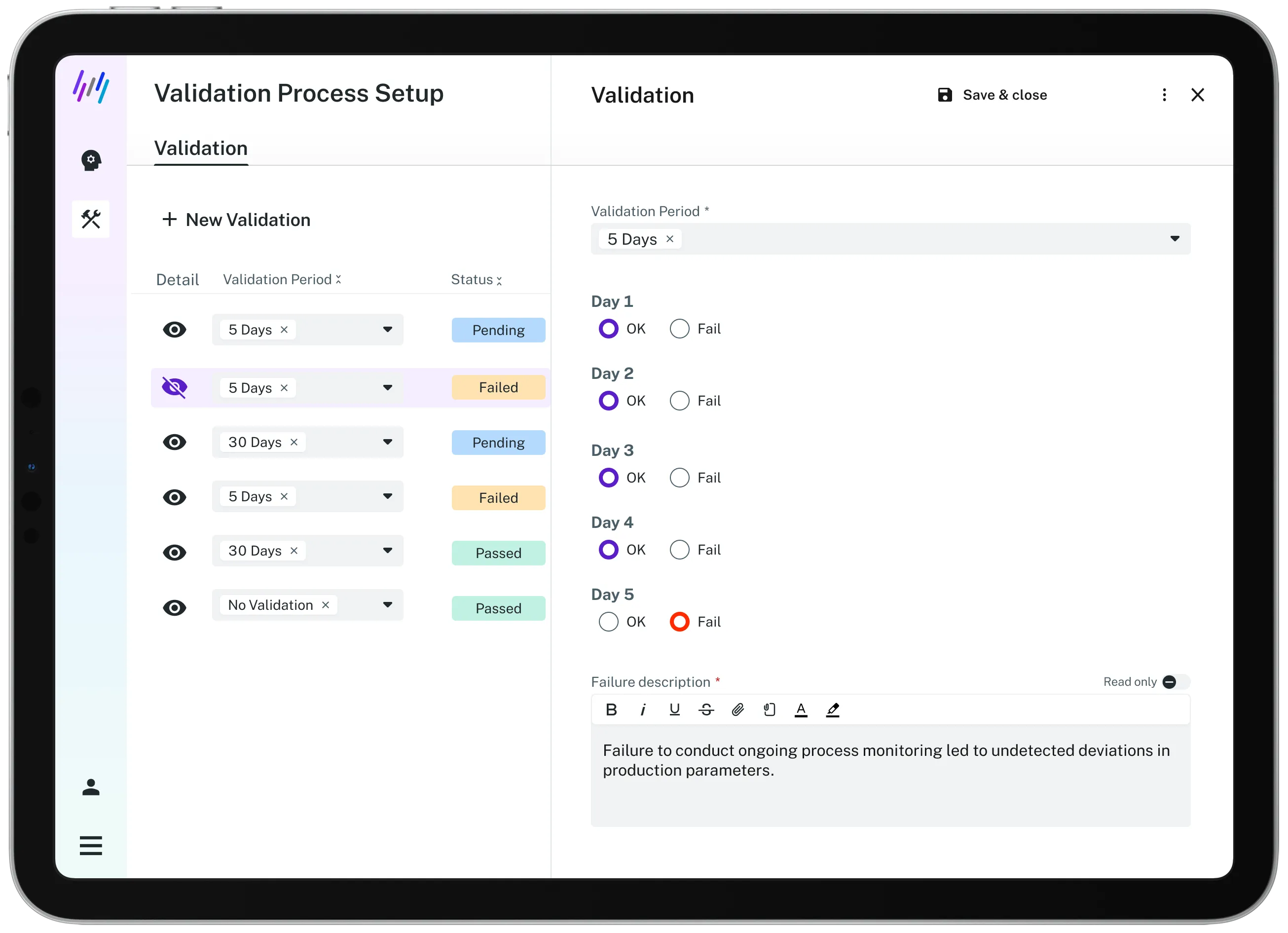

Set up a Validation Process

Set the validation process and its length, monitor the effectiveness of corrective actions with proactive alerts, and ensure continuous improvement.

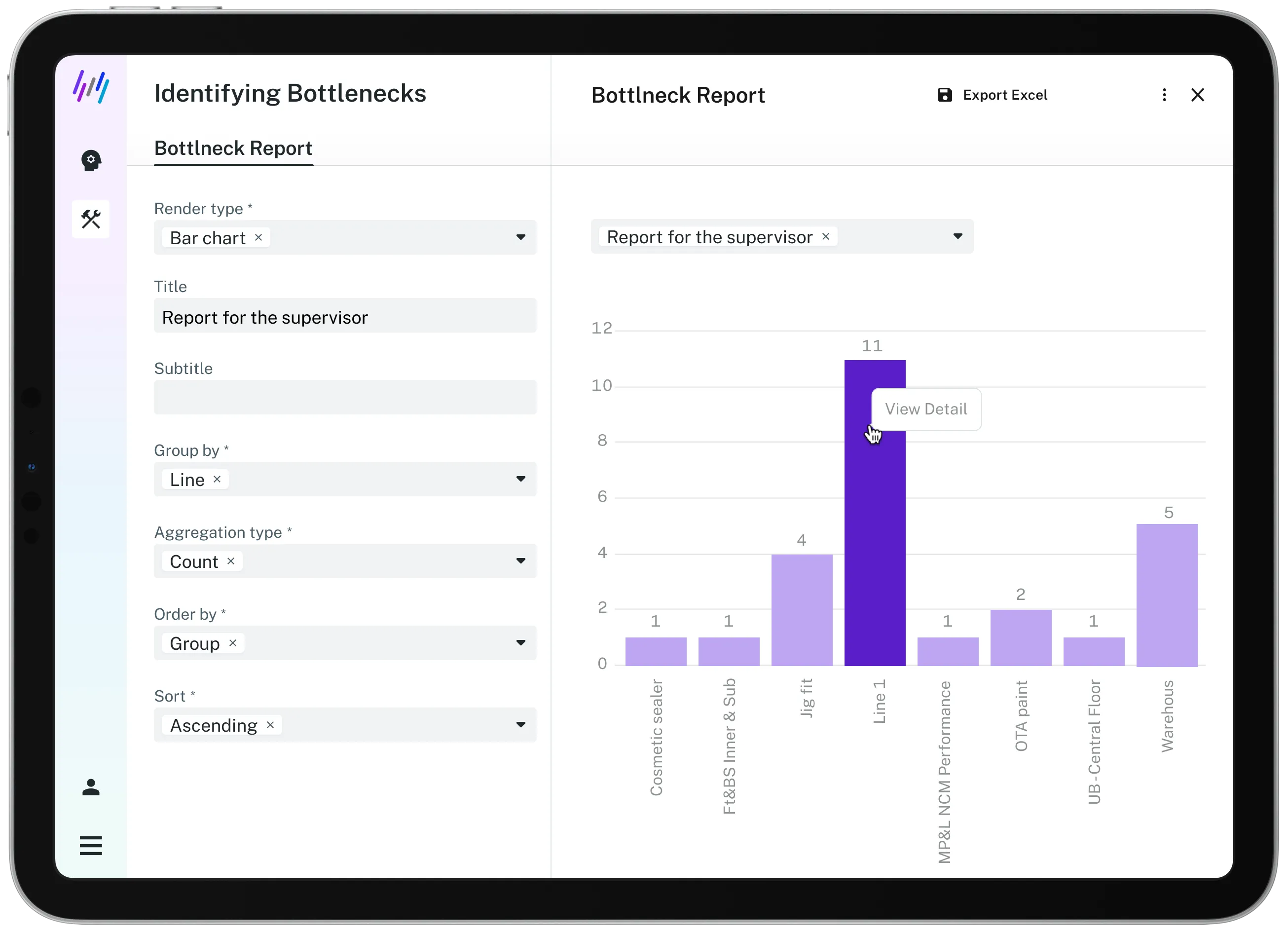

Identifying bottlenecks in production

Automatically monitor processes and use analysis to identify activities that cause long waiting times and delays.

Quality Management

Take advantage of the fully automated 8D. Its intuitive interface enables teams to quickly and efficiently solve and fix problems regarding quality.

Join the successful companies that have already improved the efficiency of their production:

Learn how to avoid production downtimes easily

Discover how our tailor-made solution aligns with your company's needs.